O1 tool steel

O1 tool steel, recognized for its exceptional versatility and performance, is widely employed in toolmaking and precision engineering applications. This alloy, renowned for its ability to be hardened in oil and superior dimensional stability, is favored in the manufacturing of cutting tools, punches, and measuring instruments.

References cited from Wiki.

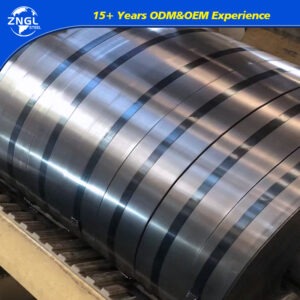

O1 tool steel

O1 tool steel is a widely used alloy in toolmaking applications. Known for its excellent wear resistance and dimensional stability, O1 steel is favored in various industries for producing cutting tools, punches, and dies.

Overview:

- O1 tool steel offers exceptional hardness and toughness, making it suitable for high-precision applications.

- It belongs to the oil-hardening cold work tool steel category, characterized by its ability to be hardened in oil.

- O1 steel is versatile and can be machined and ground to precise tolerances.

- Healthy inventories of A36 steel plate are maintained in all Zhongneng distribution centers.

- Widely utilized in tool and die making, as well as in manufacturing gauges and measuring tools.

- Available for online purchase via Zhongneng Pro. Click here to contact us to learn more.

What is O1 tool steel equivalent to?

OHNS O1 cold work steel is an equivalent of DIN 2510. The grade AISI O1 tool steel is an oil-hardening, non-shrinking tool steel and has a good cutting edge retention, high hardenability and dimensional stability during heat treatment.

What is O1 steel good for?

It is well suited for demanding applications that require precision and reliability. Its high carbon content (0.95 -1.1%) contributes to its excellent hardness, allowing tools made from O1 to maintain sharp edges and resist deformation during use. The inclusion of chromium in the alloy enhances hardenability.

Is O1 better than 1095?

1095 only has iron carbide, which aluminum oxide can make easy work of. O-1 is loaded up with chromium carbides and, depending on the flavor, a pinch of either vanadium or tungsten carbide. Even in the annealed condition these carbide will resist your sanding much more than 1095s cementite.

What is the difference between O1 and O2 tool steel?

What is the toughest tool steel?

The hardest tool steels are those with a high vanadium content. The tool steel category with the highest percentage of vanadium is the cold working tool steel, which has excellent wear resistance