Specifications for Spring Steel

| GRADES COMPARISON FOR SPRING STEEL | ||||||||

| CHINA GB/T | USA ASTM | JAPAN JIS | GERMANY DIN | FRANCE NF | BIRTAIN BS | ISO | KOREA KS | TAIWAN CNS |

| 65 | 1065 | SUP2 S65-CSP | 60E | XC65 | 060A67 | C60E4 | ||

| 70 | 1070 | S70C-CSP | 60E | XC70 | 070A72 | 8458-3 DAB | ||

| 85 | 1084 | SUP2 SK5-CSP | C85E | XC85 | 060A86 | 8458-2 DH | SUP1 | SUP3 |

| 65Mn | 1566 | S60C-CSP | CK67 | 080A67 | C60E4 | |||

| 55Si2Mn | 9255 | SUP 6 SUP7 | 55Si7 | 55Si7 | 251H60 | 55SiCr7 | ||

| 55SiMnVB | ||||||||

| 60Si2Mn | 9260 | SUP 6 SUP7 | 65Si7 | 65Si7 | 251H60 | 61SiCr7 | SUP3 | SUP6 |

| 60Si2MnA | 9260 | SUP 6 SUP7 | 65SiMn5 | 55Cr7 | 251H6 | 61SiCr7 | SUP3 | SUP6 |

| 60Si2CrA | 65SiCr7 | 65SiCr7 | 685H57 | 55SiCr6-3 | ||||

| 60Si2CrVA | 65SiCr7 | 55SiCr6-3 | ||||||

| 55SiCrA | ||||||||

| 55CrMnA | 5155 | SUP9 | 55Cr3 | 55Cr3 | 527A60 | 55Cr3 | SPS5 | SUP9 |

| 60CrMnA | 5160 | SUP9A | 55Cr3 | 55Cr3 | 527A60 | SPS5A | SUP9A | |

| 60CrMnMoA | 4161 | SUP13 | SPS9 | SUP13 | ||||

| 50CrVA | 6150 | SUP10 | 51CrV4 | 51CrV4 | 735A51 | 51CrV4 | SPS6 | SUP10 |

| 60CrMnBA | 51B60H | SUP11A | 52MnCr83 | 60VrB3 | SPS67 | SUP11 | ||

Different type for Spring iron

- Low Carbon Spring steel: Contain up to 0.3% carbon. They are highly ductile, making them ideal for applications requiring extensive forming and welding.

- Medium Carbon Spring steel: Contain between 0.3% and 0.6% carbon. These plates offer a good balance of strength and ductility, suitable for machinery parts and automotive components.

- High Carbon Spring steel: Contain between 0.6% and 1.0% carbon. They are known for their high strength and hardness, often used in cutting tools and high-strength wires.

- Ultra-High Carbon Spring steel: Contain between 1.0% and 2.1% carbon. These plates are extremely hard and are used in specialized applications like knives and springs.

Advantage of Spring steel

Corrosion Resistance Treated for excellent corrosion resistance, extending service life and reliability.

High Strength and Durability High tensile strength and durability, suitable for heavy-duty applications.

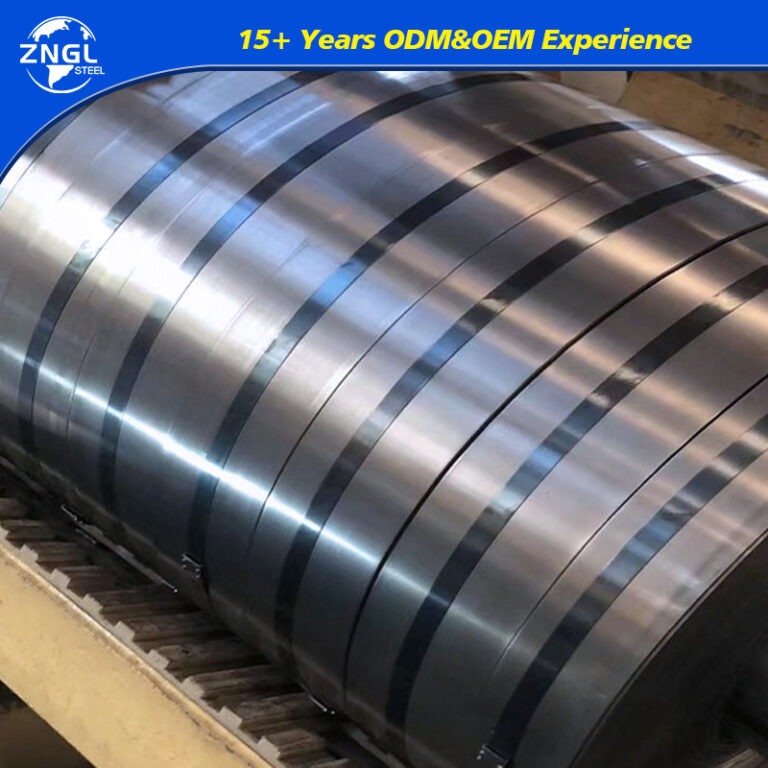

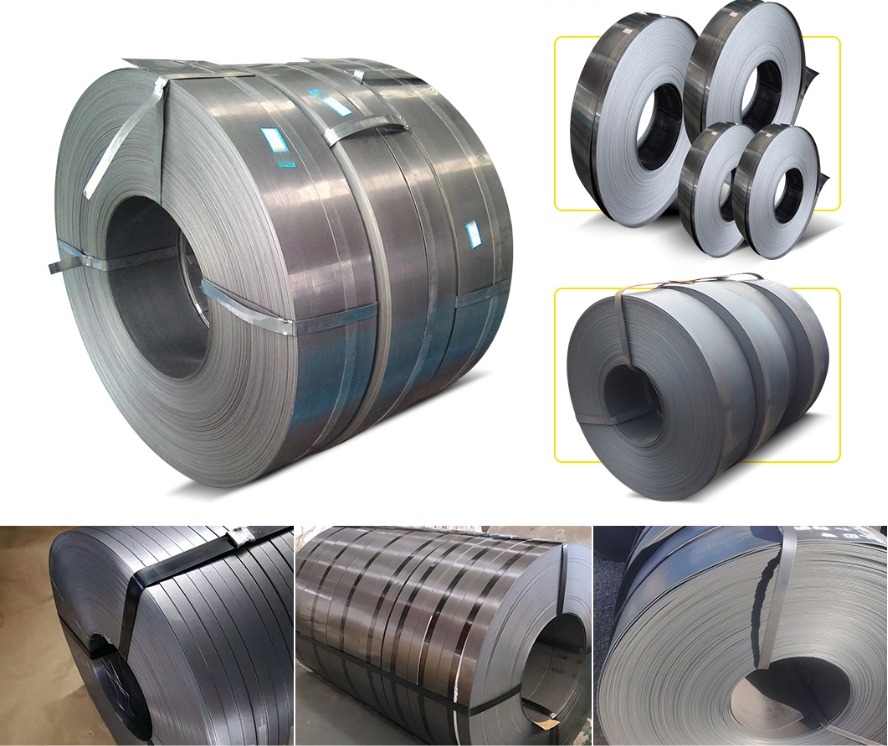

Good Workability Smooth surface and uniform thickness, easy to cut, weld, and form.

Variety of Specifications Available in various sizes and thicknesses, adaptable to different applications.

Cost-Effective More affordable than other steel types, economical for large projects.

Wide Range of Applications Versatile, used in construction, manufacturing, machinery, shipbuilding, and oil and gas industries.