Specifications for Color Steel Tile

| Specifications and Details | |

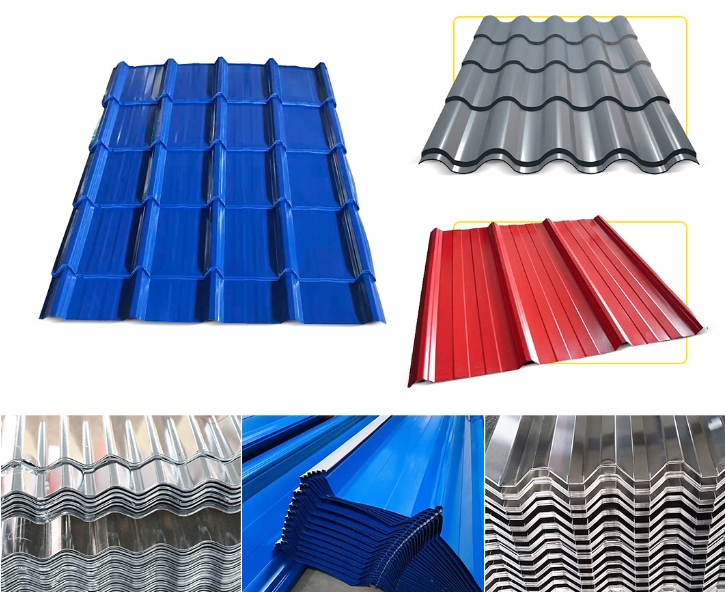

| Product name | Color Steel Tile |

| Type | Steel Plate |

| Thickness | 0.12~2.0mm |

Width | 600mm~1500mm |

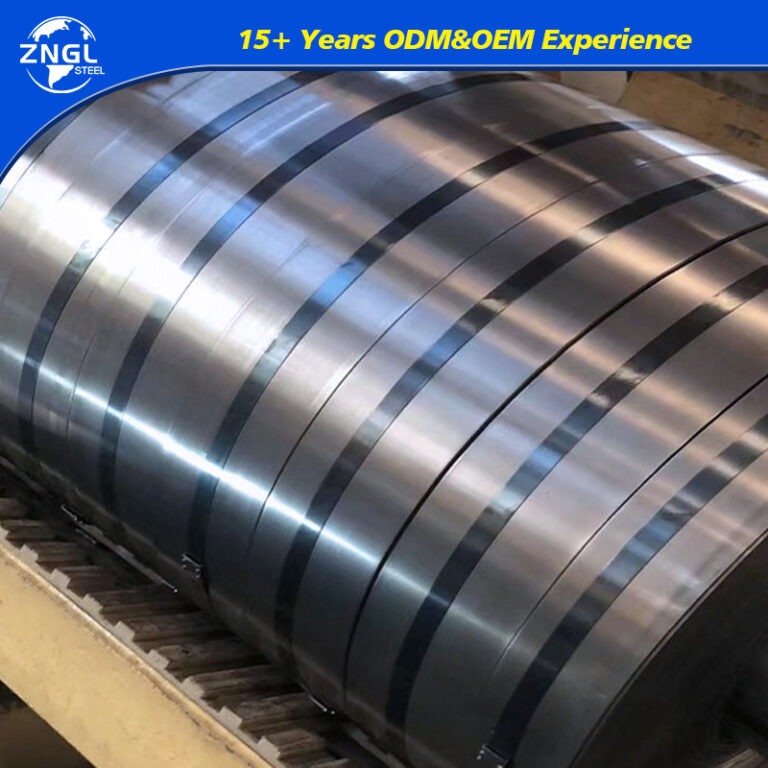

Zn Coating | 0.13-0.8mm is 30-150 g/㎡; 0.8-1.5mm is 30-180 g/㎡; 1.5-6.0mm is 30-275 g/㎡ |

Coil Weight | 3-6mt |

| Color | RAL Colors or as customer requirements |

| Surface treatment | Top paint:FVDF,HDP,SMP,PE,PU Prime paint: Polyurethane,epoxy,PE Back paint:epoxy,modified polyester |

Standard | ASTM,JIS,EN |

Certificate | ISO,CE |

Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

Key point

- Corrosion Resistance: The color steel tile features a protective zinc coating and paint layer that offer superior protection against rust and corrosion. This makes it an ideal choice for use in harsh environments, ensuring longevity and reliability.

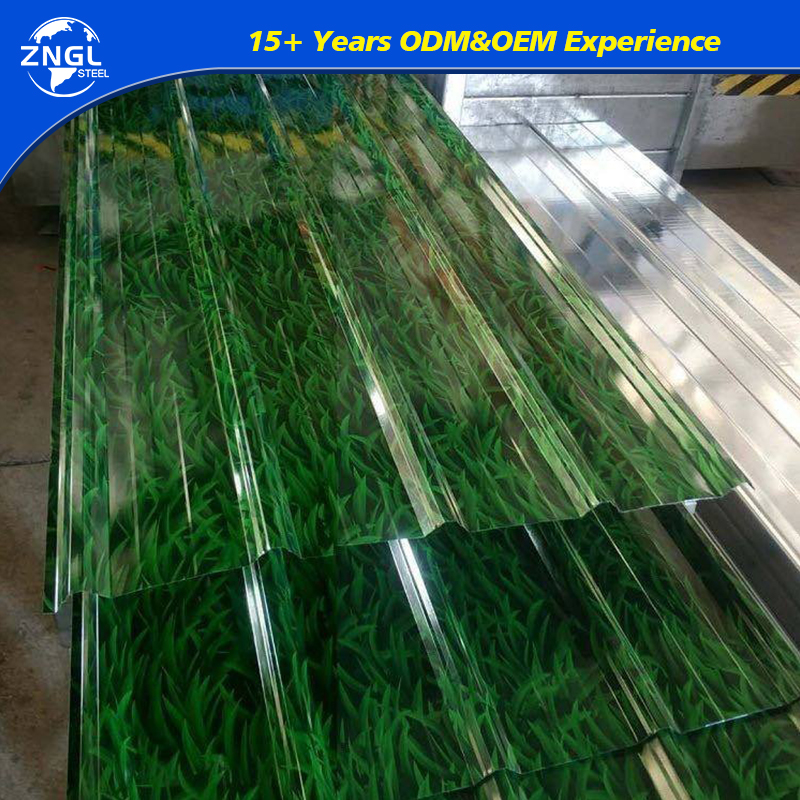

- Aesthetic Appeal: Available in a wide range of colors and finishes, color steel tiles can be customized to meet specific design requirements. Their versatility makes them a popular option in construction and architectural projects, allowing for creative and visually appealing designs.

- Durability: The combination of galvanized steel and a protective paint layer makes color steel tiles highly durable. They are designed to withstand challenging conditions, ensuring a long lifespan with minimal maintenance, making them a reliable choice for various applications.

- Cost-Effective: Despite their high-quality features, color steel tiles are relatively affordable. They provide a cost-effective solution for a variety of uses, from roofing to wall cladding, offering both performance and value.

Heat Treatment Process

- Annealing: Color steel tiles undergo annealing to soften the steel for easier processing. The steel is heated to 760-790°C (1400-1450°F) and then slowly cooled, making it easier to form, coat, and paint.

- Hardening: Although more relevant to high-strength steel, hardening involves heating and oil-quenching the steel. This process balances hardness and ductility, ensuring the tiles can withstand various conditions.

- Tempering: Tempering reheats the steel to 150-350°C (300-660°F) and then cools it. This step enhances the durability and flexibility of the color steel tiles, making them suitable for diverse applications.

Applications of Color Steel Tile

- Roofing and Cladding: Color steel tiles are widely used for roofing and cladding in residential, commercial, and industrial buildings due to their durability, weather resistance, and aesthetic appeal.

- Fencing and Gates: The strength and corrosion resistance of color steel tiles make them ideal for constructing long-lasting fences and gates.

- Architectural Panels: These tiles are commonly used in architectural panels, offering both structural support and a range of design possibilities with various colors and finishes.

- Sheds and Garages: The lightweight yet strong nature of color steel tiles makes them a popular choice for building sheds, garages, and other outbuildings where easy installation and low maintenance are important.