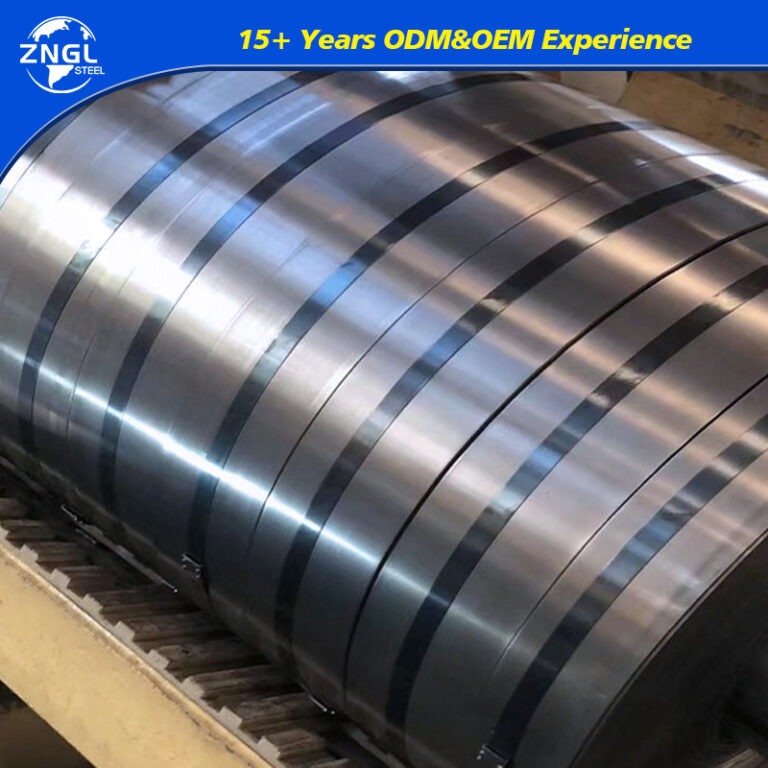

Specifications for Pre-Galvanized Steel Coil

| Specifications and Details | |

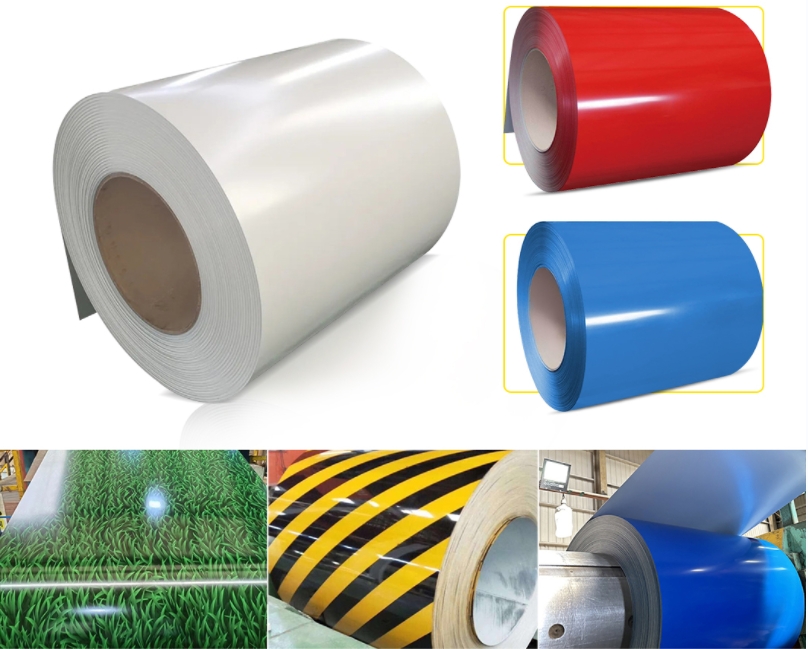

| Product name | Pre-painted Galvanized Steel Coil |

| Type | Steel Coil |

| Thickness | 0.12~2.0mm |

Width | 600mm~1500mm |

Zn Coating | 0.13-0.8mm is 30-150 g/㎡; 0.8-1.5mm is 30-180 g/㎡; 1.5-6.0mm is 30-275 g/㎡ |

Coil Weight | 3-6mt |

| Color | RAL Colors or as customer requirements |

| Surface treatment | Top paint:FVDF,HDP,SMP,PE,PU Prime paint: Polyurethane,epoxy,PE Back paint:epoxy,modified polyester |

Standard | ASTM,JIS,EN |

Certificate | ISO,CE |

Processing Service | Welding, Punching, Cutting, Bending, Decoiling |

Key point

- Corrosion Resistance: The zinc coating and paint layer on PPGI provide excellent protection against rust and corrosion, making it ideal for use in harsh environments.

- Aesthetic Appeal: PPGI is available in a wide range of colors and finishes, allowing for customization to meet specific design requirements, making it a popular choice in construction and architecture.

- Durability: The combination of galvanized iron and protective coatings makes PPGI highly durable, ensuring a long lifespan with minimal maintenance, even in challenging conditions.

- Cost-Effective: Despite its high-quality features, PPGI is relatively affordable, offering a cost-effective solution for a wide range of applications, from roofing to appliance manufacturing.

Heat Treatment Process

- Annealing: In the production of PPGI, steel is often annealed to soften it before further processing. Annealing involves heating the steel to a temperature between 760-790°C (1400-1450°F) and then slowly cooling it in a furnace to 480°C (900°F) before allowing it to air cool to room temperature. This process makes the steel easier to work with, ensuring it can be easily formed, coated, and painted.

- Hardening: While hardening is more relevant to high-strength steel products, understanding this process helps in the context of PPGI. Hardening involves preheating the steel to 400-650°C (750-1200°F) and then raising the temperature to 780-820°C (1440-1500°F) before quenching in oil. This process is designed to achieve the desired hardness in steel products. For PPGI, maintaining a balance between hardness and ductility is key to ensuring the coated steel can withstand various environmental conditions.

- Tempering: Tempering is a critical process in steel treatment, aiming to achieve the right balance between hardness and toughness. Steel is reheated to 150-350°C (300-660°F) depending on the desired outcome, held at this temperature for an hour per inch of thickness, and then air-cooled. For PPGI, the tempering process of the base steel contributes to the durability and flexibility required for its wide range of applications, including roofing, cladding, and appliances.

Applications of PPGI

- Cutting Tools: O1 steel is ideal for manufacturing various cutting tools, including knives, punches, and dies due to its high wear resistance and edge retention.

- Molds and Dies: Used in injection molds, extrusion dies, and other forming tools where precision and durability are critical.

- Industrial Blades: Commonly used for making industrial blades that require a sharp and long-lasting edge.

- Measuring Tools: Due to its dimensional stability, it is used in precision measuring tools like gauges and micrometers.