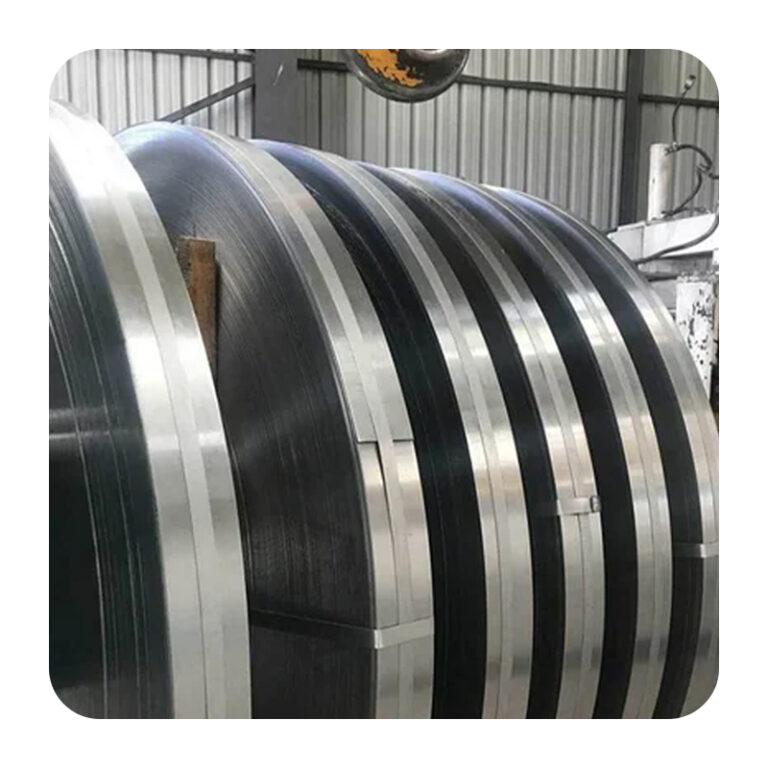

Spring steel

Spring steel is a specialized alloy widely employed for its unique mechanical properties in various industrial applications. This type of steel is distinguished by its high yield strength and elasticity, making it ideal for the manufacturing of springs and components requiring resilience under repetitive loading conditions.

References cited from Wiki.

A36 steel/Mild steel

Spring steel, renowned for its exceptional resilience and flexibility, is a specialized alloy extensively utilized across diverse industrial applications. This steel variant is recognized for its unique mechanical properties, primarily its high yield strength and elasticity, which render it indispensable for manufacturing components designed to withstand cyclic stress and deformation.

Overview:

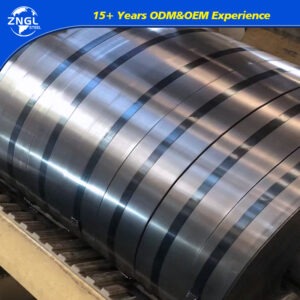

- Spring steel alloys play a crucial role in industries requiring components capable of enduring repeated loading and deformation.

- Available in a variety of grades and compositions tailored to specific application needs, ensuring optimal performance under varying conditions.

- Manufactured to stringent standards to guarantee consistent mechanical properties and reliability.

- Traditionally, it has been pivotal in the production of automotive suspension systems, mechanical springs, and high-performance machinery.

- Modern advancements continue to enhance the durability and versatility of those alloys, expanding their utility across aerospace, automotive, and manufacturing sectors.

- Available for online purchase via Zhongneng Pro. Click here to contact us to learn more.

What is spring steel material?

Spring steel is a name given to a wide range of steels used in the manufacture of different products, including swords, saw blades, springs and many more. These steels are generally low-alloy manganese, medium-carbon steel or high-carbon steel with a very high yield strength.

Is spring steel stronger than carbon steel?

Mechanical Properties: Carbon steel has good strength and ductility, making it suitable for a wide range of applications. Spring steel, on the other hand, excels in elasticity and resilience, making it ideal for springs and other components that require repeated bending and stretching.

Is spring steel the same as regular steel?

Spring steel is a unique and versatile material with exceptional properties such as high yield strength, elasticity and resilience. Its composition and heat treatment processes set it apart from regular steel, making it ideal for various applications, including springs, clips, fasteners, and machinery.

Can spring steel rust?

Does spring steel hold an edge?

After heat treating 1095 steel is a simple carbon steel alloy known for its hardness, toughness, and ability to hold a sharp edge. With proper heat treating you can attain hardness up to Rockwell C 58. 5160 steel is a tough metal with lower edge retention

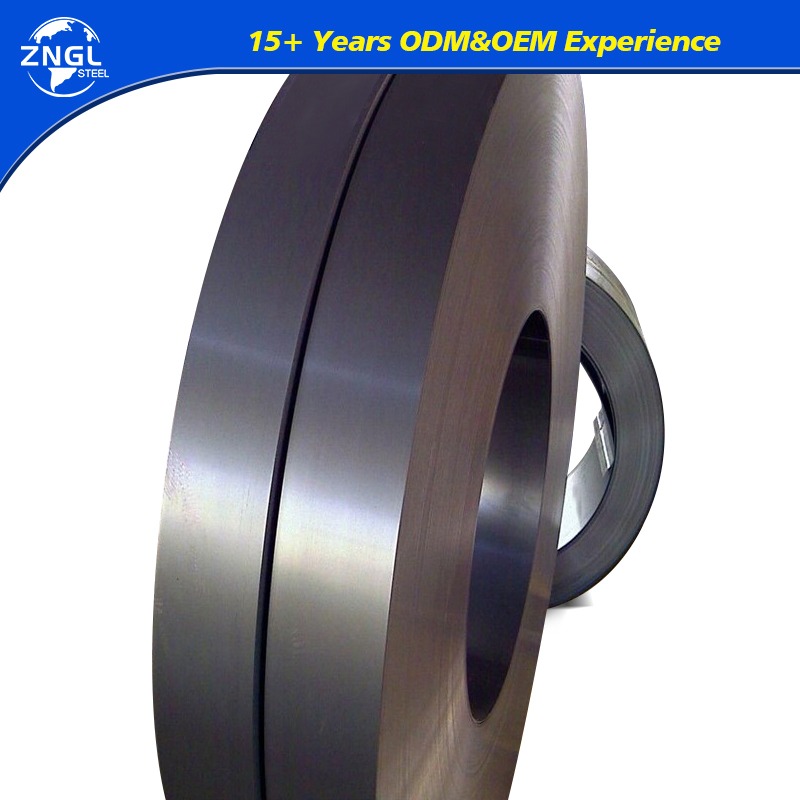

Why is spring steel so hard?

The process of hardening spring steel is the other important step in giving the material its high yield strength. Hardening can occur through heat treatment or a process referred to as work hardening—the hammering, rolling, drawing or other physical means that can be applied to increase its hardness.